Top Helical Gear Manufacturers in India

Helical Gears: The Power of Precision

Helical Gears: The Power of Precision

Welcome to Sethi Gear, a renowned name among India’s top helical gear manufacturers. With our expertise in producing high-quality gears, we prioritize precision and reliability to meet your gear requirements effectively.

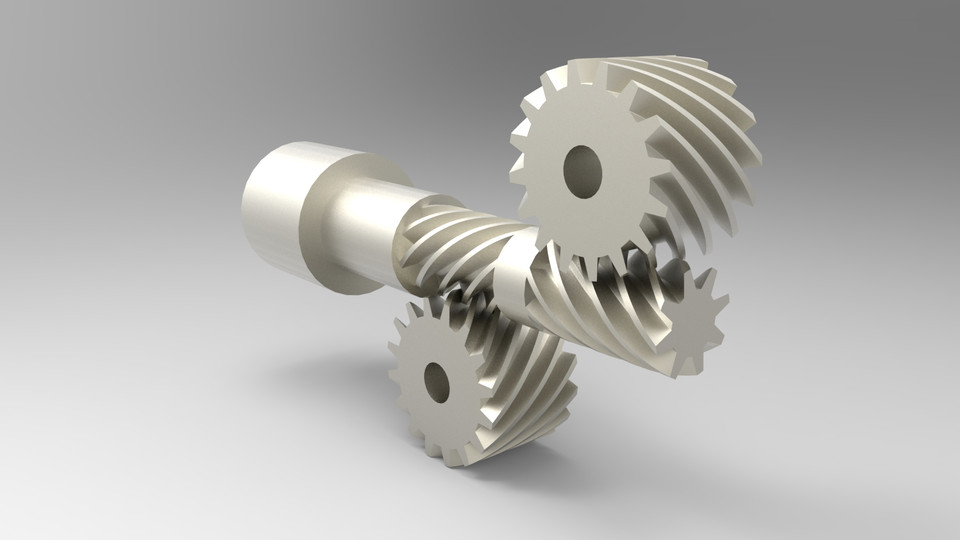

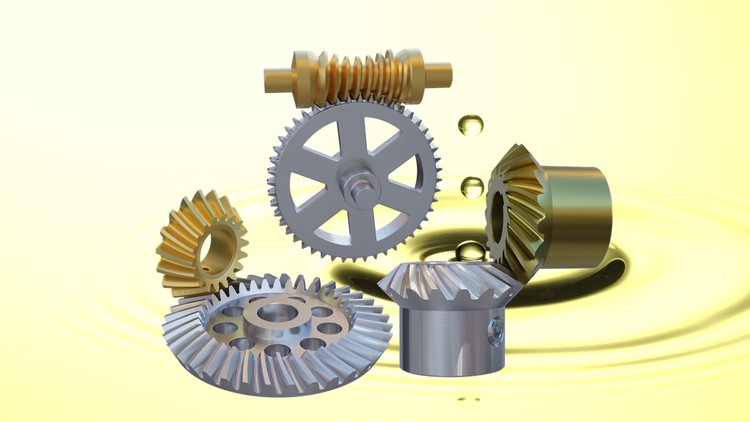

Embark on a fascinating journey into the captivating realm of helical gears, where the fusion of exactness and strength takes centre stage. Helical gears, an indispensable element in numerous machinery and mechanisms, flawlessly transmit rotational motion with unparalleled precision.

These gears, distinguished by their distinctive spiral-shaped teeth, offer many benefits compared to other gear types, including heightened load-carrying capacity, seamless operation, and reduced noise emissions. Helical gears are crucial in delivering unwavering performance in automotive transmissions, industrial equipment, or even everyday household appliances.

Come and explore the intricacies of helical gears, unveiling the secrets behind their unmatched accuracy and ensuring the seamless and efficient functioning of an extensive range of applications.

Helical Gear Manufacturing Process in India

Helical Gear Manufacturing Process in India

Helical gears are a crucial part of many industries, and their manufacturing process in India exemplifies a commitment to quality and precision. These manufacturing processes are given below:

1. Design and Engineering: The process begins with the design and engineering of the helical gear, considering factors such as tooth profile, module, pressure angle, and gear ratio. Computer-aided design (CAD) software is commonly used to create precise gear specifications.

2. Material Selection: The appropriate material for the helical gear is chosen based on load requirements, operating conditions, and durability. Common materials include alloy steel, carbon steel, and stainless steel.

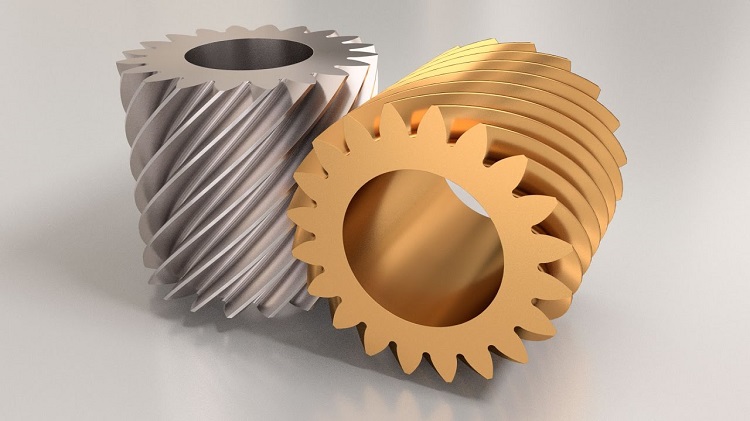

3. Gear Cutting: The gear-cutting process involves shaping the gear teeth. The most common methods used are hobbing and milling. Hobbing uses a rotating cutting tool called a hob to generate the teeth gradually. Milling uses a rotating cutter to remove material and create the desired tooth profile.

4. Heat Treatment: After the gear teeth are cut, heat treatment is applied to improve the hardness and strength of the gears. Carburizing, quenching, and tempering are commonly employed to achieve the desired material properties.

5. Finishing Operations: Finishing operations include grinding, honing, and lapping to achieve precise tooth dimensions, surface finish, and gear accuracy. These processes ensure smooth and accurate gear operation.

6. Inspection and Quality Control: The manufactured helical gears undergo a rigorous inspection to check for dimensional accuracy, tooth profile, surface finish, and other quality parameters. This is done using various inspection tools and techniques, such as coordinate measuring machines (CMM) and gear analyzers.

7. Assembly: If necessary, the helical gears are assembled with other components, such as shafts, bearings, and housings, to create gearboxes or assemblies.

8. Testing and Validation: The finished helical gears are tested to ensure their performance meets the required specifications. This may include load testing, noise testing, and durability testing.

9. Packaging and Delivery: Once the helical gears pass all quality checks, they are packaged securely and prepared for customer delivery.

It’s important to note that the specific manufacturing process may vary based on the gear’s complexity, the manufacturer’s production methods, and the desired gear specifications.

Harnessing the Advantages of Helical Gears Manufacturing in India

Harnessing the Advantages of Helical Gears Manufacturing in India

1. Increased Load Capacity: Helical gears distribute the load over multiple teeth, resulting in higher load-bearing capacity than other gear types. This allows for the transmission of greater torque and power.

2. Smooth and Quiet Operation: The helical tooth profile enables gradual and progressive engagement of the gear teeth, reducing vibration and noise during operation. This makes helical gears ideal for applications where noise reduction is crucial.

3. Efficiency and Power Transmission: Helical gears are more efficient than other gear types, as they minimize sliding friction between the teeth. This leads to improved power transmission and energy efficiency in gear systems.

4. Versatility and Flexibility: Right-angle drives, crossing shafts, and parallel shafts are just a few examples of the different configurations that helical gears may be utilized in. Numerous applications across several sectors are possible because of this adaptability.

5. Better Tooth Meshing: The helical tooth design provides a larger contact area between gear teeth, resulting in smooth and uniform tooth meshing. This ensures a more even distribution of forces, reducing wear and enhancing gear longevity.

6. Overlapping Tooth Engagement: Helical gears have a longer contact ratio, with multiple teeth in contact simultaneously. This distributes the load more evenly, reducing the risk of tooth breakage and enhancing gear strength.

7. Higher Precision: Helical gears can be manufactured with high precision, ensuring accurate tooth profiles and gear geometries. This precision leads to reliable and consistent gear performance.

8. Heat Dissipation: The helical gear design allows for better heat dissipation due to the larger surface area of the gear teeth in contact. This helps to dissipate heat generated during gear operation, preventing overheating and prolonging gear life.

Helical gear manufacturing offers advantages such as increased load capacity, smooth operation, efficiency, versatility, precision, and improved heat dissipation. These factors make helical gears a preferred choice for various industries, including automotive, machinery, aerospace, and more.

Helical Gear Uses: Unlease Their Versatility

Helical Gear Uses: Unlease Their Versatility

1. Automotive Industry: Helical gears are commonly found in automotive transmissions, enabling smooth and efficient power transfer between the engine and wheels. They help optimize gear engagement, resulting in reduced noise and vibration levels.

2. Industrial Machinery: Helical gears are essential in various industrial machinery applications, including conveyors, pumps, compressors, and mixers. They facilitate precise speed reduction or increase, ensuring reliable and accurate operation.

3. Robotics and Automation: Helical gears are vital in robotic systems and automation equipment. They enable precise movement and torque transmission, improving mechanical operations’ overall efficiency and accuracy.

4. Power Generation: In power generation plants, helical gears are used in turbine systems, gearboxes, and generators. They effectively transfer rotational energy, enabling the conversion of mechanical power into electrical energy.

5. Marine Applications: Helical gears are employed in marine propulsion systems, where they assist in transferring power from the engine to the propeller. They offer efficient torque transmission and help achieve smooth and quiet operation.

6. Aerospace Industry: Helical gears are utilized in various aerospace applications, such as aircraft landing gear systems, engine components, and actuators. They contribute to the reliable and precise functioning of critical aerospace mechanisms.

7. Machine Tools: Helical gears are integral to machine tools like lathes, milling, and gear-cutting. They enable accurate and smooth movement, ensuring precision in shaping and cutting operations.

8. Printing and Packaging: Helical gears are employed in printing presses and packaging machinery. They assist in controlling the movement and synchronization of various components, ensuring precise printing and packaging processes.

9. Medical Equipment: Helical gears are utilized in medical equipment such as diagnostic imaging machines, robotic surgery systems, and patient beds. They enable precise motion control and efficient power transmission within these critical healthcare devices.

10. Agricultural Machinery: Helical gears are found in agricultural equipment like tractors, harvesters, and irrigation systems. They aid in the power transmission of different farm processes, facilitating efficient farming operations.

Why Did We Choose Sethi Gears as India's Top Helical Gear Manufacturer?

Why Did We Choose Sethi Gears as India's Top Helical Gear Manufacturer?

Sethi Gears stands out as the top choice for helical gear manufacturers in India for several compelling reasons:

1. Extensive Industry Experience: With years of expertise, Sethi Gears deeply understands helical gear manufacturing, ensuring reliable and high-quality products.

2. Cutting-Edge Technology: Sethi Gears employs advanced machinery and manufacturing techniques, producing precise and efficient gear.

3. Customization Capability: The company offers tailor-made solutions to meet unique requirements, delivering customized helical gears for diverse industries.

4. Commitment to Quality: Sethi Gears maintains strict quality control measures, ensuring that its helical gears meet rigorous performance and durability standards.

5. Timely Delivery: The company prioritizes on-time delivery, leveraging streamlined processes and supply chain management to meet client deadlines.

Choose Sethi Gears for their expertise, technological prowess, customization options, dedication to quality, and reliable delivery, making them India’s top helical gear manufacturers.

If you are looking for the top gear manufacturers in India than Sethi Gear is the best option for you.

Top Helical Gear Manufacturers in India

Top Helical Gear Manufacturers in India

Suppose you live in India and want the services of a trusted manufacturer of helical gears. In this situation, we have compiled a list of India’s best spiral gear producers recognized for their high level of customer care. Using this list, you may identify a reputable Indian helical gear manufacturing firm that can suit your unique requirements, whether you need gears for automotive, industrial, or other purposes.

Sethi Gear

Sethi Gear Industry, formerly known as Sethi Industrial Corporation, was established in 1956. Our modern manufacturing unit facility is in Delhi. We are counted as the top worm gears manufacturers in India.

With vast and in-depth knowledge, Sethi Gear has now emerged as the leading gear manufacturer in Delhi. We are modern in the engineering industry. We offer highly efficient, durable, reliable mechanical transmission and engineering products.

Sokhi Heli-Wom Gears Private Ltd

A company that may be regarded as “Manufacturers and Concept Development Engineers combined with consultancy and design” is Sokhi Heli-Wom Gears. The premium selection of industrial gears and power transmission equipment supplied by Crescent guarantees maximum performance in various sectors. Their business has provided the gearbox and gearing industry with outstanding quality and trustworthy service.

Saggu Gears India

Since its establishment in 1992, “Saggu Gears India” has become one of the leading companies involved in producing, distributing, and exporting gears, gearboxes, and machinery spare parts. Our organization’s main goal is to deliver reliable performance and quality items. Their extremely effective products are used in various industries because of their grades, including durability, high tensile strength, and corrosion resistance.

Manjeet Traders

For many years, Lotus Vario has offered a variety of top-quality items. Their hardworking crew keeps track of their inventory and provides clients with high-quality goods. They are certain that they can meet your needs at a competitive price. They work with all varieties of motors and gearboxes.

Their business is putting a lot of effort into finding the most recent, pertinent research in gear technology. Supported by a skilled group of engineers and a quality control staff. The demonstrated abilities of all of their products are acknowledged in both the domestic and international markets.

J V Gears India

With over 20 years of expertise, they are a leading manufacturer of Industrial Gearboxes and Gears. Their specialization lies in designing and manufacturing high-quality Helical Gears, Spur Gears, Extruder Gearboxes, Pinion Shafts, Crane Duty Gearboxes, and more. They prioritize delivering products that meet stringent quality standards and provide excellent performance.

Their experienced team ensures precision in design and manufacturing processes. They take pride in offering reliable and durable solutions to their customers in various industries.

FAQs

FAQs

Some of the top spiral gear manufacturers in India are:

- Sethi Gear

- Sokhi Heli-Wom Gears Private Ltd

- Saggu Gears India

- Manjeet Traders

- J V Gears India

When choosing a helical gear manufacturer, consider factors like their experience, reputation, quality assurance processes, manufacturing capabilities, customization options, delivery times, pricing, customer support, and reviews from other clients.

Yes, Sethi Gear offers customization services. They can design and manufacture helical gears based on your requirements, such as gear specifications, tooth profile, material, size, and other parameters.

Yes, Sethi Gear, India’s top helical gear manufacturer, can handle large-scale production orders. It’s advisable to contact the manufacturers directly to discuss your specific requirements and production volume.

Yes, Sethi Gear typically provides after-sales support and warranty for its products. It’s recommended to inquire with the specific manufacturer regarding the details of their after-sales support and warranty policies.

Yes, helical gears manufactured in India are known for their high quality. Several top manufacturers in India follow strict quality assurance processes to ensure the durability and performance of their helical gears.